Light Resin Transfer Molding

Light Resin Transfer Molding (LRTM) is similar to RTM but uses a vacuum to hold the male & female tools together. This process will give you two finished sides and a pretty high tolerance for part thickness & dimensions. Because it is held together by vacuum and not hydraulic pressure, heavy metal tooling is not required, making tooling less expensive. Light RTM is an excellent process for manufacturing parts that require both inside and outside finished surfaces.

Process – Fiberglass mat patterns are loaded into the female tool. The male tool is set into the female tool, then a vacuum is applied to pull each other together. All of the air is vacuumed out of the part and then the resin is hooked up and pulled through the part. The tool stays under vacuum till the resin is cured and then the part is pulled.

LRTM needs

- Components are designed to their exact specifications

- Components made from quality materials

- Skilled and professional technicians

- Regular updates on their projects

- Prompt and timely results

Components We Can Create With LRTM

With the Light Resin Transfer Molding process, clients can get components that are perfect within the automotive, transportation, and recreation industries.

Here are some of the components that we regularly manufacture for our clients:

- Fenders

- Truck Roofs

- Cowl Panels

- Engine Covers

- Cooling Modules

- Door Surrounds

- Battery Boxes

- Exterior Trims

Precision in LRTM Molds

As with any composite closed mold production process method, LRTM demands high-quality, accurate cross-section molds in order to provide good mold life and consistent production of repeatable parts. This is a key element to successful molding and is a common oversight for those who venture into either LRTM or RTM on their own. We strongly encourage those who wish to take advantage of the closed molding processes of RTM or LRTM, to allow us to be a major part of achieving their success.

Light Resin Transfer molding or Light RTM is another versatile process that works well for a number of applications. Common applications include marine, aerospace, building or construction, and automotive industries. Increase your productivity and let Painted Rhino handle your LRTM projects!

Efficient LRTM Process

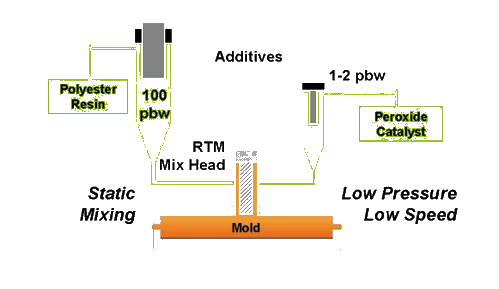

Our LRTM Composites process involves an airtight closed mold, which consists of two sides: the “A” side, which is the base, and the “B” side or the counter mold. Resin can be injected to speed up resin infusion into the mold and vacuum pressure is used to conform the material. Once cured, the B side is removed and the resulting part is removed from the base. With quick cycles and production rates using multiple molds, LRTM is efficient and cost-effective. Because the process uses a closed mold, it reduces VOC emissions in the workspace.

Prazastinav Compositech Pvt Ltd has been a long-standing leader in closed mold technology for years with the developments of key techniques and accessories to complement its advanced injection equipment. The MVP technical support specialists travel the globe to offer comprehensive training and educational opportunities for manufacturers to learn more about closed molding procedures and techniques.