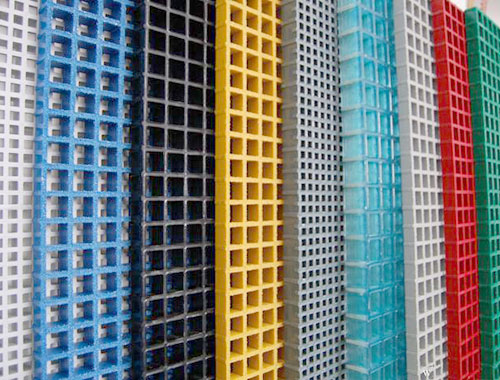

PRAZASTINAV offers wide range of Moulded Grating & Pultruded Grating,

Traditionally Steel gratings were being used for various applications. But COMPOSITE GRATINGS due to various advantages over steel like better strength, durability, lightweight, non-corrosion, aesthetics, etc. have been extensively tested and increasingly used across industries for various innumerable applications.

Composite Gratings are also known as FRP (Fibre Reinforced Plastic) gratings or GRP (Glass glass-reinforced plastic) gratings or FRP Composite gratings. FRP/GRP are basically composite materials made of plastic reinforced by fine fibres made of glass and other additives

Provides superior corrosion resistance in addition to significant bi-directional strength (square mesh panels). With 35% glass and 65% resin content Moulded grating is the choice for exceptional resistance to chemical attack along with the benefit of bi-directional strength to reduce the need for additional support to be added when cutting penetrations through the grating.

With 11 standard resin systems on hand to meet the most demanding corrosive environments along with 'special' formulations that can be created to suit exceptional requirements.

The high percentage of resin (65%) in moulded fiberglass grating offers superior corrosion resistance and optimal impact resistance. Moulded fiberglass gratings with a square mesh pattern offer increased load capacity and panel utilization due to its bi-directional trait.

Numerous cut-outs for piping, valve access, and column penetrations can be made without the need for additional structural framing. Being of one-piece construction, the fiberglass grating performs as a plate, distributing loads throughout the fiberglass grating section and around cut-outs. Cutting access holes in the moulded fiberglass grating does not weaken the panel and does not generally require additional or costly supports (unlike Pultruded fiberglass grating that will require additional supports at cut-outs).

- Pultruded fiberglass grating offers the highest levels of uni-directional strength and stiffness. With 65% glass and 35% resin content Pultruded grating is the choice for larger span requirements.

Three resin systems are available to meet the need for every environment:

• ISOFR - isophthalic polyester resin formulation with a low flame spread rating of 25 or less designed for applications where there is a moderate exposure to corrosive elements.

• VEFR - vinyl ester resin system with a flame spread of 25 or less for dependable resistance to both acidic and alkaline environments.

• PHENOLIC - flame resistant phenolic resin with an extremely low flame spread of 5 or less and a smoke index of 45 or less - designed primarily for the offshore industry.

This type of FRP grating offers builders a wide variety of panel sizes, and flexibility because it is assembled and not moulded. This helps to reduce waste, or scraps of FRP in comparison to the moulded fiberglass grating process.